- Home

- Products

- Numerical Control Surface Grinders

- SSG-818 / SSG-1224 SSG-1632 / SSG-1640

SSG-818 / SSG-1224 SSG-1632 / SSG-1640

- This machine is the crystallization of the technology that Fushun has carefully researched for many years. It has a stable appearance and a strong structure. Various operating handles and movable operating panels are within the operator's best line of sight and the most comfortable operating position. This is in line with the ergonomic design. Excellent models, providing you with higher work efficiency.

- Spindle mechanism: The spindle is supported by five ultra-precision beveled ball bearings. Stable and strong main shaft structure, can withstand heavy load grinding.

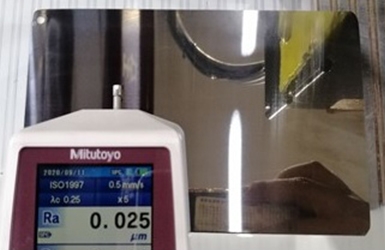

- AC servo motor lift drive: C3-level drive screw, driven by AC servo motor, with large torque, fast speed, and high positioning accuracy. With the full CNC system, the feed accuracy can reach 0.0001mm or 0.001mm.

- Two lines and one hard track: Z-axis and Y-axis purchase high-precision line rails, and cooperate with high-precision ball screws, which can make the action smooth without lag; , maintaining accuracy without distortion.

- Front and rear transmission speed control: The continuous movement speed of the saddle is driven by AC servo motor to obtain good surface grinding accuracy.

| Item | 單位 | SSG-818 | SSG-1224 | SSG-1632 | SSG-1640 | |

|---|---|---|---|---|---|---|

| Table size | mm | 200x460 | 300x600 | 400x800 | 400x1000 | |

| Max. Grinding length | Longitudinal | mm | 460 | 610 | 810 | 1015 |

| Max. Grinding width | Crosswise | mm | 200 | 305 | 405 | |

| Distance table to centerline of wheel | mm | 405 | 600 | |||

| Standard Magnetic Chuck Size | mm | 200x460 | 300x600 | 400x800 | 400x1000 | |

| Longitudinal Movement of Table | Travel, Hydraulic | mm | 460 | 650 | 850 | 1050 |

| Table speed, varible | m/min | 5~25 | ||||

| Cross Movement of Table | Rapid Travel, Approx. | m/min | 0~2.25 | |||

| Auto Increment | mm | 3~32 | ||||

| Max. Automatic Travel | mm | 220 | 320 | 420 | ||

| Micro Feed | mm | 0.0001 | ||||

| Wheelhead Vertical Infeed | Automatic Infeed | mm | 0.0001~0.04 | |||

| Rapid Travel, Approx. | mm/min | 675 | ||||

| Micro Feed | mm | 0.0001 | ||||

| Grinding Spindle Drive | Speed | Hz/rpm | 60/3450 | 60/1750、50/1450 | ||

| Power Rating | Hp(Kw) | 4 (3) | 7.5 (5.625) | |||

| Standard Grinding Wheel | OD | mm | 203 | 355 | ||

| Width | mm | 12.7 | 50 | |||

| Bore | mm | 31.75 | 127 | |||

| Hydraulic Drive | Power Rating | Hp(Kw) | 1 (0.75) | 2 (1.5) | ||

| Crossfeed Drive | Power Rating | KW | AC 0.75 / 1.1 | |||

| Elevating Drive | Power Rating | KW | AC 0.75 / 1.1 | |||

| Machine dimensions | Floor space (W x D x H) | mm | 2400x1500x1780 | 2850x1900x2000 | 3150x2250x2000 | 3560x2250x2000 |

| Weight | Net weight | Kg | 1700 | 2350 | 3100 | 3700 |

| Gross weight | Kg | 2100 | 2800 | 3750 | 4350 | |

| Rated Power (Approx.) | Hp(Kw) | 6 (4.5) | 10 (7.5) | |||

- All content is for reference only and may be subject to change without notice or obligation.

- The total suggested maximum workloads of table are shown as follows:

- A=Workpiece B=Magnetic Chuck C=A+B

| Item | SSG-818 | SSG-1224 | SSG-1632 | SSG-1640 |

|---|---|---|---|---|

| A | 175 | 314 | 403 | 42 |

| B | 35 | 106 | 197 | 247 |

| C | 210 | 420 | 600 | 670 |

- Machine Lamp

- Single Face Dresser

- Parallel Dressing Attachment (Manual)

- Frequency Inverter

- Wheel Flange

- Balancing Stand

with Leveling Bubble - Electromagnetic Chuck

- Chuck Controller

- Double Side Water Baffle

- Over the wheel automatic straight line dressing and compensation device

- Parallel Dressing Attachment (hydraulic crossfeed, manual downfeed)

- Dust Collector

- Coolant System

- Coolant System with Automatic Paper Feeding

Device and Magnetic Separator

Coolant System with Magnetic Separator

(with 1 roll of paper) - Coolant System with Automatic Paper Feeding

Device (with 1 roll of paper)